Lean & Sustainable Factory 2023

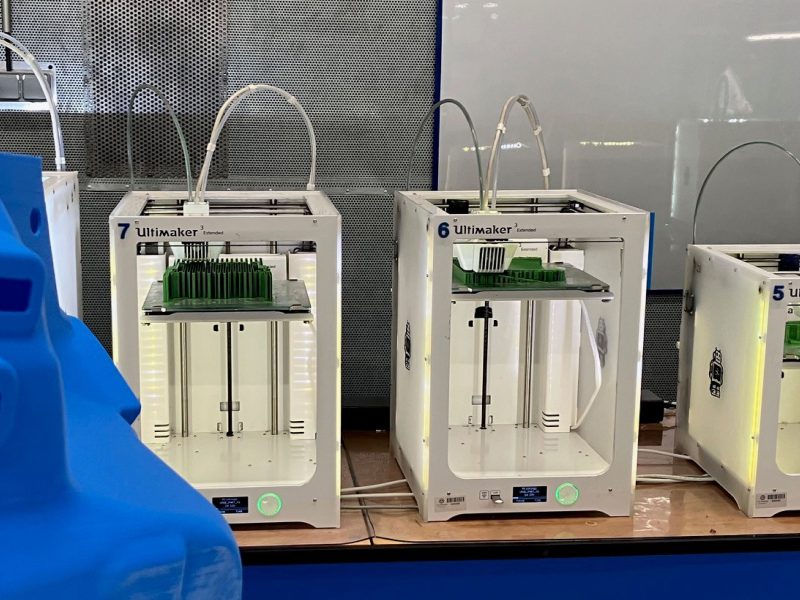

3D-Printing

Pilot Plant

-

Frontloading activities for product feasibility studies

Scroll for measure details

-

3D-Printing

Area

PMP | Pilot Plant

Implementation date

2019 (newest)

Before

The validation of product related changes in an early stage of the development phase can only be possible via the regular CAD systems or by means of prototype parts that are very costly and very difficult to manufacture. Under these conditions a quick and accurate validation from the production site is barely achievable.

After

With the usage of 3D-Printing the validation of product related changes can be easily made through 3D-printed hardware parts, thus enhancing the speed and accuracy of the validation. This means that proper feedback from the production site can be quickly integrated in the product optimization cycles throughout the complete development phase.

Project figures | |

|---|---|

Investment | 21,4 T€ |

Saving | NA |

Results/improvements | Shorter reaction time between development and manufacturing (frontloading). Less need of costly prototyping tools and/or parts in order to validate product related changes. |

21,4 T€

NA

Shorter reaction time between development and manufacturing (frontloading). Less need of costly prototyping tools and/or parts in order to validate product related changes.